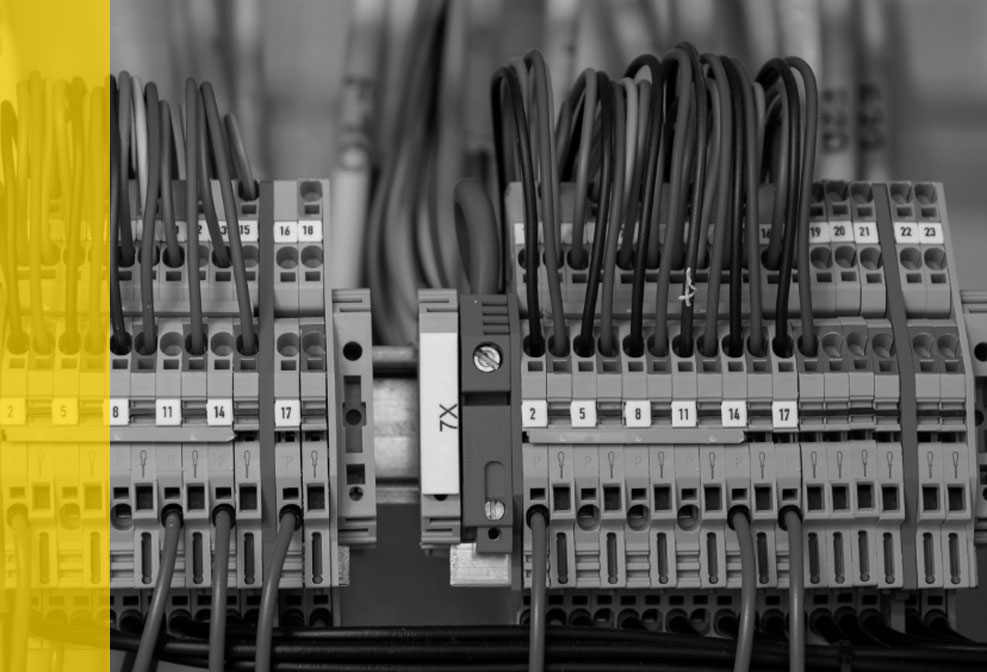

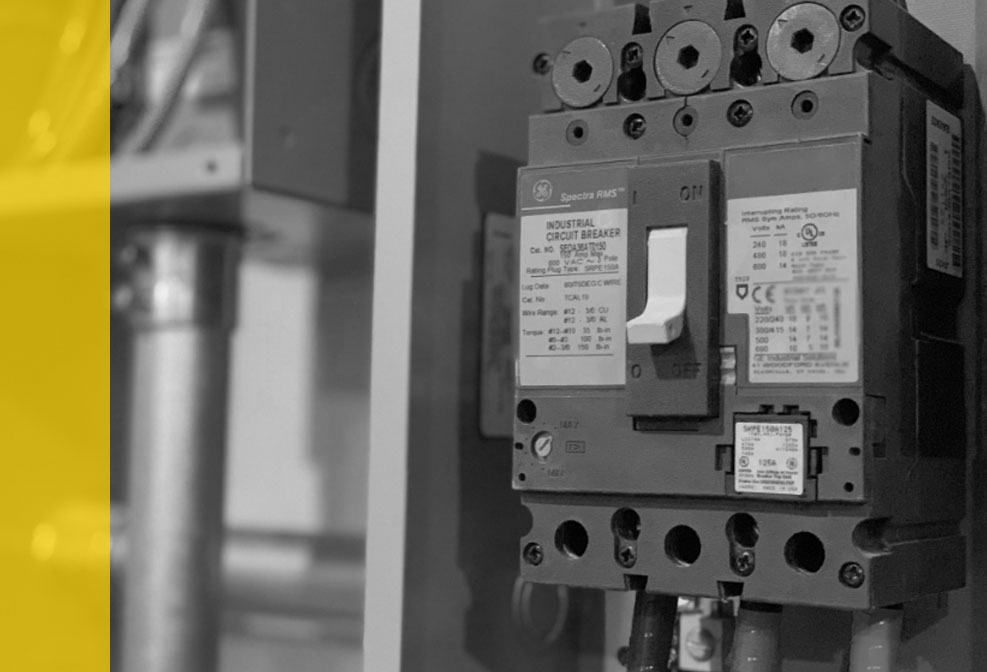

Circuit breakers:

Make and break all currents within the scope of their ratings, from small inductive and capacitive load currents up to the full short circuit current, and this under all fault conditions in the power supply system, such as earth faults, phase opposition, and so on.

Switches:

Switch currents up to their rated normal current and make on existing short circuits (up to their rated short circuit making current).

Disconnectors (isolators):

Used for no-load closing and opening operation. Their function is to isolate 'downstream' devices so they can be worked on.

Three-position disconnectors:

Combine the functions of disconnecting and earthing in one device. Three-position disconnectors are typical for GIS - Gas insulated switchgear.

Switch disconnectors (load break switches):

The combination of a switch and a disconnector, or a switch with isolating distance.

Contactors:

Load breaking devices with a limited short circuit making or breaking capacity. They are used for high switching rates.

Earthing switches:

To earth isolated circuits.

Make-proof earthing switches (earthing switches with making capacity):

Are used for the safe earthing of circuits, even if voltage is present, that is, also in the event that the circuit to be earthed was accidentally not isolated.

Surge arresters:

To discharge loads caused by lightning strikes (external overvoltage) or switching operations and earth faults (internal overvoltage). They protect the connected equipment against impermissibly high voltages.

Fuses:

Consist of a fuse base and a fuse link. With the fuse base, an isolating distance can be established when the fuse link is pulled out in de-energized condition (like in a disconnector). The fuse link is used for one single breaking of a short circuit current.

Nowadays, vacuum switchgear getting popularity very rapidly. Since, vacuum circuit breaker is more safely and reliably operated where number of faulty and normal operation is much high. In medium voltage switchgear application, vacuum switchgear ranges from 3 to 36 KV. The performance of a circuit breaker mainly depends upon the dielectric medium used for arc quenching. Another major advantage of this technology, is that vacuum switchgear is nearly maintenance free.

Rapid Arc Quenching

During opening of contacts in current carrying condition, metal vapour is produced between the contacts, and this metal vapour provides a path through which electric current continuous to flow until the next current zero. This phenomenon is also known as vacuum arc. This arc is extinguished near the current zero and the conductive metal vapour is re-condensed on the contact surface in a matter of micro seconds. It has been observed that, only 1% of the vapour is re-condensed on arc chamber's side wall, and 99% of vapour re-condensed on the contact surface from where it was vaporized.

Low Arc Energy in Vacuum

The energy dissipated during arc in vacuum is about one tenth of that of oil and one fourth of that of SF6 gas. Low energy dissipation mainly due to low interruption time (due to small contact gap) and small arc length (this is also due to small contact gap). Because of this low arc energy dissipation, vacuum switchgear has negligible contact erosion and this gives it nearly maintenance free life span. It is also to be noted that, for breaking certain current, the energy required by vacuum circuit breaker is minimum compared to air circuit breaker and oil circuit breaker.

Dielectric Strength of Vacuum

For a given contact gap, vacuum provides, about eight times more dielectric strength than air and four times more dielectric strength than SF6 gas at one bar. As the dielectric strength is so high, the contact gap of vacuum circuit breaker can be maintained very small. In this small contact gap, arc quenching is safely possible due to high dielectric strength and also vacuum has the fast recovery strength after full arc interruption to its full dielectric value at current zero. This makes vacuum switchgear most suitable for capacitor switching.

Simple Driving Mechanism

In SF6, oil and air circuit breaker, movement of contacts is highly resisted by highly compressed medium of arc quenching chamber. But in vacuum switchgear, there is no medium, and also movement of contacts is quit less due to its small contacts gap, hence driving energy required is much smaller, in this circuit breaker. That is why simple spring-spring operating mechanism is sufficient for this switchgear system, no need of hydraulic and pneumatic mechanism. Simpler driving mechanism gives a high mechanical life of vacuum switchgear.

From above discussion, it is almost clear that, the dielectric strength of vacuum switchgear recovers very fast and contact erosion is almost negligible.

VCB panel's use has following advantages:

All the components are segregated through each other for having metal sheet. The degree of protection IP4X for the indoor application and IP54/55 for the outdoor applications, protection and metering with the numerical or static or electromagnetic meters and relays according to customer's requirement, racking in or out of the breaker from the test for service position and vice versa having cubical door blocked, mechanical I/l for preventing racking in or out for breaker while on the condition, drawing out kind PT having fuses and broad busbar compartments capable of height for the cable compartment.

Product Features

The whole series of VCB panel products is accepted for the features including:

Performance

All these VCB quality checks may be organized via application of intelligent testing instruments installed in the product examination laboratory.

VCB (Vacuum Circuit Breaker) Range

There are many types of VCB panels available that delivers superior performance. For preventing the fires as well as power surges, VCB are utilized in the areas where the electric crisis can occur. These VCB get application in the medium voltage system. Different kinds of VCB are given here:

Outdoor Panels

The outdoor panels come with the TVM VCB that is appropriate for the outdoor installations. Any unsafe situation that may result because of electric exigency may be prevented through these panels. This circuit range is appropriate for the medium ranged electric current. These panels are durable, sturdy, and offers consistence performance. Furthermore, these circuits are very cost effective.

Porcelain Clad VCB

Porcelain clad VCB can be placed on the base with the area adjoining a factory. Power is supplied through the cable boxes or the roof bushing or the combination of cable and roof bushing. Earthing in all the circuit breakers may be performed through the integral earthing switches, slowing close kind or through making the capacity or via draw-out of earthing the truck with the solid links for bus feeder or bar side. These circuit breakers are very cost effective as well as provides consistence performance.

VCB Trolley

The VCB Trolley is very easy in installations and also very durable. The trolleys are mainly used in the electric as well as power supply industries.

Definition

1."Can't be opened" means that the circuit breaker cannot open normally and make the power off. The characteristics of the "Can't be opened" fault are: the circuit light plate is on and the signal board shows the protection action, but the red light of the circuit is still on. The backup protection of the previous level is as follows. The main transformer compound voltage overcurrent, circuit breaker failure protection and other actions. In some cases, the backup protection cannot act in time, the component will have a short-term increase in the indication value of the ammeter, the indication value of the voltmeter will decrease, the pointer of the power meter will shake, the main transformer will emit a heavy buzzing abnormal noise, and the corresponding circuit breaker is still in closing position.

2. "Can't be closed" means that the circuit breaker cannot normally close and send power.

Failure reason

Processing method

If the circuit breaker refuses to trip and lead to override trip, firstly check the protection and the action of the circuit breaker.

Some customers asked about advantages of embedded pole that compared to assembly pole, we would like to introduce that here.

Epoxy embedded poles, or called embedded vacuum interrupters, vacuum interrupters with epoxy resin, is made by casting vacuum interrupters, main circuit conduct and mounting parts with epoxy into an integral part.

The main advantages of this technology (compared to an assembled or open pole system) are its high dielectric strength as well as better protection against environmental influences. Embed the vacuum interrupter in resin make the pole particularly sturdy and protect the interrupter from impacts, dust deposits and humidity. The design is compact, robust and modular. Another important advantage is the fast and easy assembly of the pretested and adjusted poles on the vacuum circuit breakers.

The embedded pole/casting resin vacuum interrupter is epoxy resin envelope, silicon liquid latex, Cu-Cr contact interrupter with long creepage distance and cup-shaped contact holder adopting axial magnetic field, installed in the accordant indoor and outdoor vacuum circuit breaker or other vacuum distribution devices. It is especially used in the electric power, mechanical, chemical and metallurgical departments as well as mines and other industrial departments where it is operated frequently.

Welcome to order embedded pole from us.

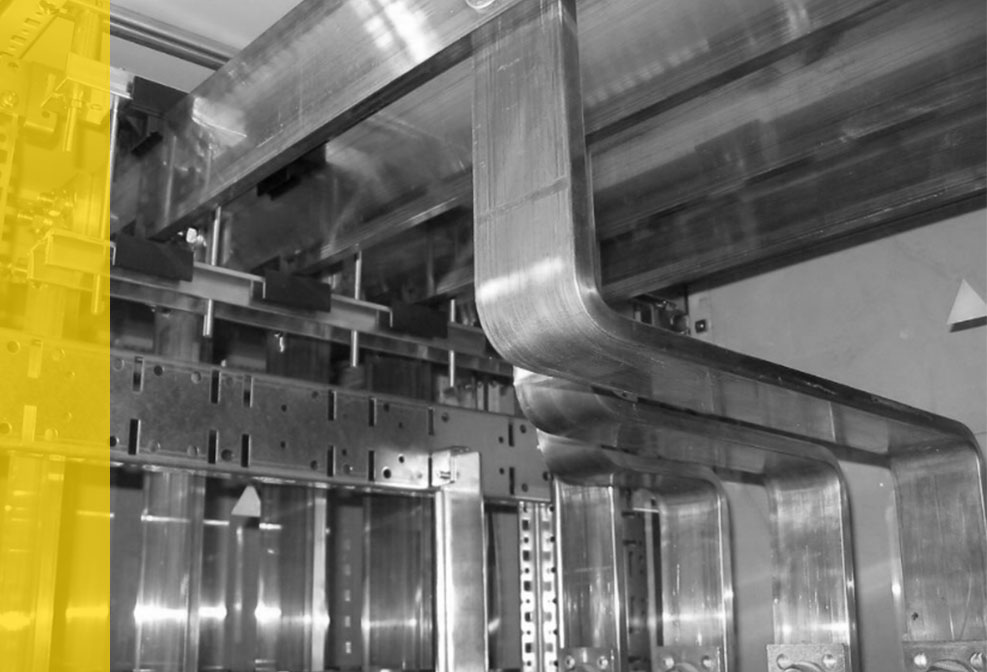

5 Considerations to Note before Entering into the Busbar Design Phase

When it comes to busbar design basics, there are 5 considerations you should take into account to help aid in system success.

Below, the bus bar manufacturers here at EMS have highlighted the most important factors to consider before entering the busbar design phase.

Busbar Material

In most cases copper will be the preferred busbar material, but there are some advantages to selecting aluminium.

Conductor Material & Dimensions

Selecting the proper conductor material is also essential for achieving the necessary electrical performance and mechanical requirements. Material options typically include copper, aluminium and various other copper alloys.

The mechanical dimensions of the conductor, including minimum width and thickness, is determined by the material selected, the mechanical requirements and the current-carrying requirements. Conductor thickness may be modified if there is a selection of tabs or terminations where studs, nuts or threaded inserts are needed.

The ground return conductor must be equal in size and circular mil area to its corresponding voltage conductor.

If minimum inductance is a busbar design requirement, you may want to consider minimizing the thickness and maximizing the width of the conductor.

Busbar Plating

Busbar plating is necessary for many applications in order to protect against corrosion and provide good contact surface, maintaining low resistant contact when attached.

Busbar Epoxy Coating

Busbar epoxy coating is necessary to protect against electrical shock, corrosion, high voltage arcing and current-induced magnetic fields. It is also used to improve conductivity.

Busbar epoxy coating is necessary within various industries particularly where harsh environment conditions exist, such as at chemical plants, nuclear plants, and on ships.

Cost Considerations

Cost for a bus bar system will vary based on numerous factors, such as materials, finish requirements, interconnection scheme and quantity.

In order to achieve the most cost-effective bus bar system, it's critical to ensure early involvement with your bus bar manufacturer. Early involvement will aid in ease of manufacturing, final product quality, turnaround time and overall cost.